ABOUT

OUR FACTORY

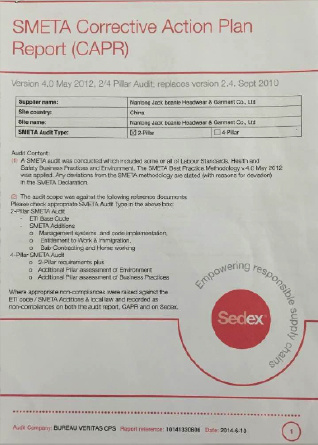

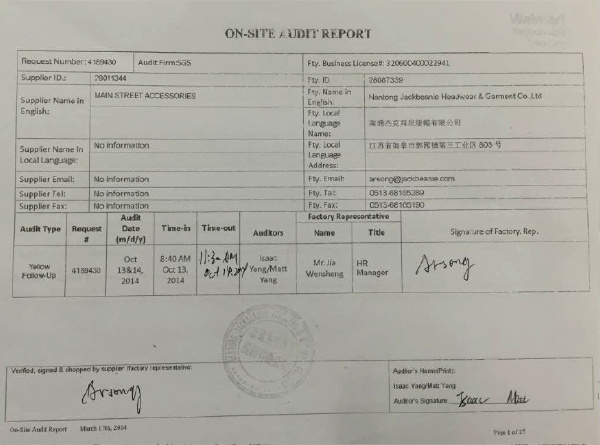

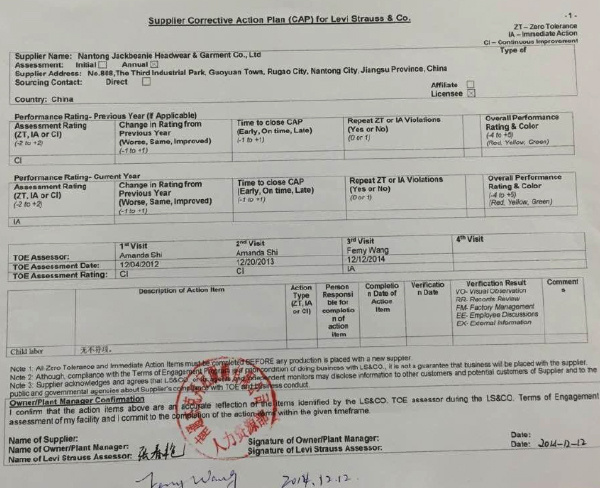

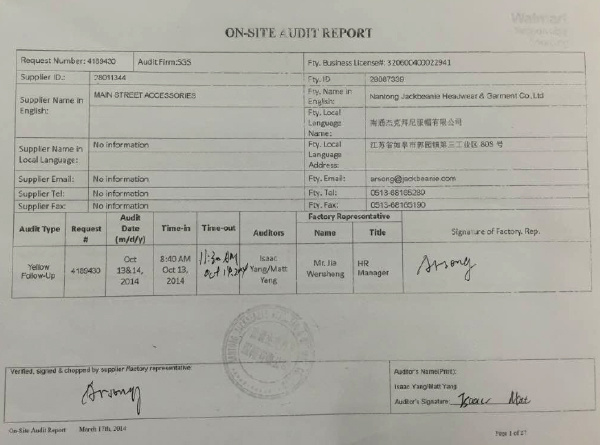

FACTORY AUDITS

SOME INFORMATION ABOUT OUR FACTORY AND THE WAY WE WORK

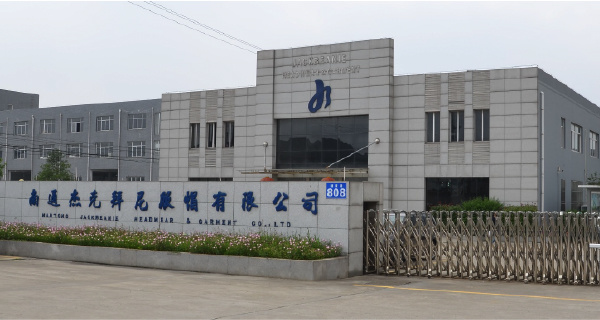

Nantong Jackbeanie Headwear & Garment Co., Ltd was established in 2010 and specializes in manufacturing caps (such as snapbacks and curved peak caps) and knitted hats (such as beanies and bobble hats).

Our factory is located at No.808, The Third Industry Park, Guoyuan Town, Rugao City, Jiangsu Province, which is approx. 2 hours from Shanghai and Shanghai Pudong Airport.

WHAT WE MANUFACTURE

At JackBeanie we manufacture many types of knitted and woven products:

● Baseball caps / snapbacks

● Woven bucket hats

● Knitted hats / beanies

● Scarves

● Gloves

● Fedoras

● Trappers

● Ivy hats

HOW WE WORK...

International Talent

We continue to employ professional, technical, and design-led people to join the JackBeanie team.

We strive to enhance our overall strength, our capability and enable us to adapt to the changing markets and competition.

Streamline Production

Internal Meetings – we continually have meetings to improve our technical and design ability

Expert Training – we invite professional experts to the factory for system training

Constant Improvement – using our experience and international guidance

Up-grade Machinery and Equipment – streamline our production workshop

MACHINERY & EQUIPMENT

Embroidery Machines

We have 16 Tajima units that are imported from Japan and we plan to add 25 Barudan units in 2016.

Jacquard Machines

We have imported the latest Jacquard machines from Japan and Germany some of which can produce the whole garment.

Other Machines

● Circular knit machine

● Magic knit machine

● Flat knit machine

● Automatic cutting machine

● Automatic visor cover stitches machine

● Automatic button covering machine

MATERIALS

Woven

Cotton Twills

108x58 20x20, 108x56 16x12, 108x56 16x10, 7x7 , 10x10

Stretch Twill

Acrylic/Spandex, Wool/Spandex, Cotton/Spandex

Polyester

AC Liner, Sports Training Mesh, Spacer Mesh, Microfibre

Performance Mesh

Amax Mesh, Trucker Mesh

Technical Fabrics

Waterproof fabric, Windproof fabric, COOLMAX, 3M, Dupont Fabric, Dri-release

Knitted

Acrylic, Soft Acrylic, Cotton, Wool, Merino Wool, Cashmere, Linen, Lamb Wool, Angora, Organic Cotton, Bamboo

Dri-release Polyester

Wool/Polyester, Waterproof

Yarns

Blend yarn, Neppy yarn, Space-dye yarn

Special Yarns

We are able to source special yarns required within the market

We prepare approx. 800 tons of greige yarn annually

SAMPLES & PRODUCTION

Samples leadtime

From regular fabrics and yarns: 7 - 10 days

From special fabrics and yarns: 15 - 25days

Production leadtime

60 - 90 days after getting PPS/client approval

20 - 35 days for VERY rush orders

MOQ

For knitted and woven products

144 pieces per order using regular yarn and fabric

2000 pieces for ‘special’ material orders

Note: The price will be higher if below MOQ

Capacity

Woven

400,000 pieces per month

Knitted

800,000 piece per month

QUALITY CONTROL

We have a quality control system using AQL 2.5 standard for all in-processing and final checks.

Some Japanese orders and other high grade brands use AQL 1.0.

Future Plans

Investment in whole garment knitting technology and 3D printing machinery.

Setting up an international team, including designers and sales in the USA and Europe.

PHOTOS AND FACTORY IMAGES

Jackbeanie Headwear & Garment Co., Ltd head office and factory is based in Nantong, China.

Our factory has passed the majority of global factory audits (see more here)

WE HAVE PASSED THE FOLLOWING AUDITS:

FLA | WCA | Quicksilver | CocaCola | Lafuma | BSCI | Sedex | New Balance | Levi’s | STR GSM | DAKINE | KOHL’S | Adidas | mothercare | Wal-mart | Norrona

E-mail:sales@jackbeanie.com

Tel: +86-513-6816 5282

Add:No.808 The third industy Park,Guoyuan Town, Rugao City, Jiangsu Province, China.

Mobile

Copyright © 2022 Nantong Jackbeanie Headwear & Garment Co., Ltd. Powered by www.300.cn SEO